This action will delete this post on this instance and on all federated instances, and it cannot be undone. Are you certain you want to delete this post?

#3dprinting 5 hashtags

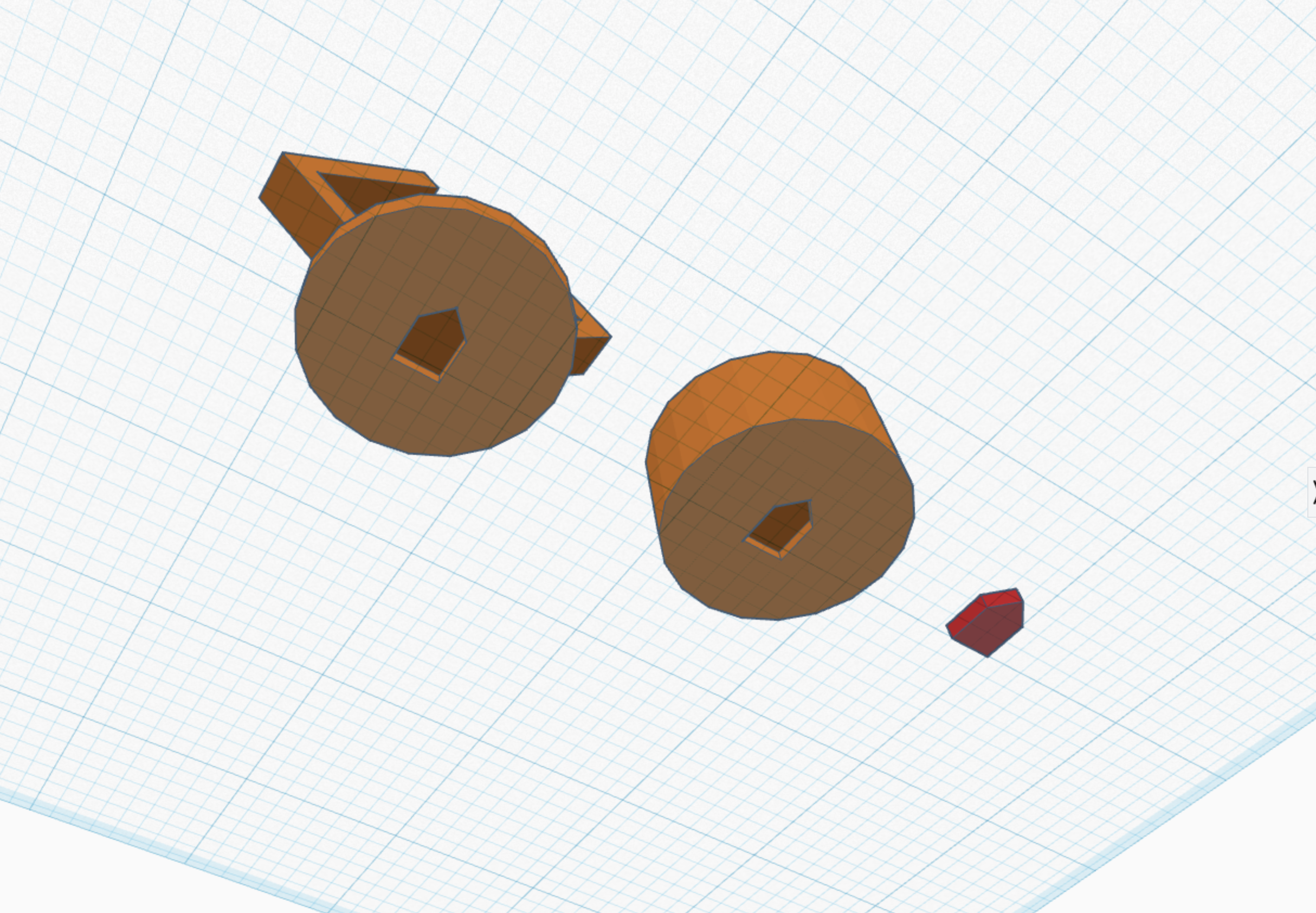

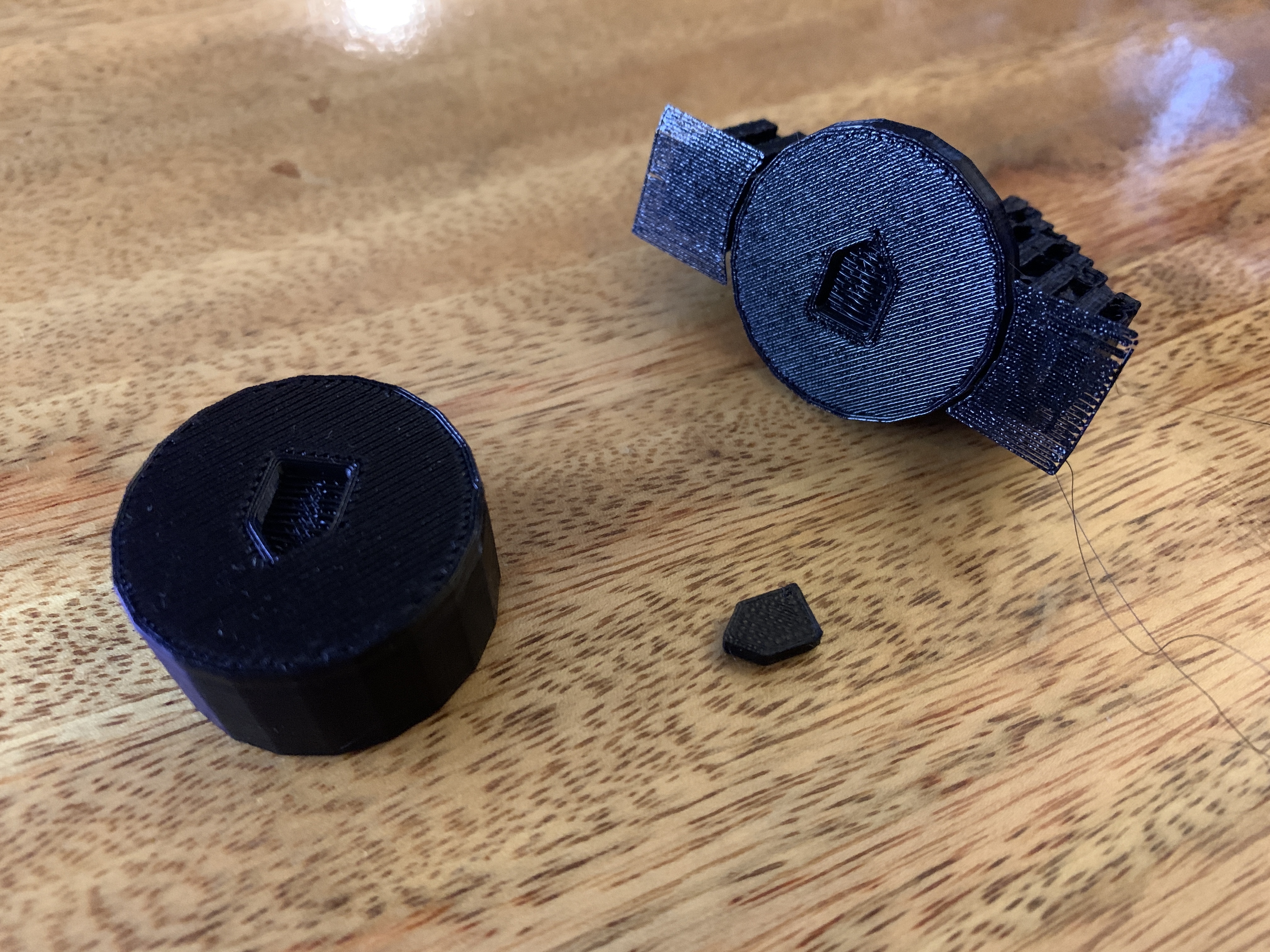

One of the things I've learned to do in my prints, when I have two parts that will be joined together, is create a directional key and matching key holes in each part. The holes should be half the depth of the key. The key and holes should fit together in one direction only. I can't count the number of times I've glued two parts together that were slightly askew, or backwards, or...

i'm getting some clicking noise from the 3d printer. probably time to read the manual...

design

print

fiddle

re-print

tweak

re-print

tune

...hours later...

print

finish

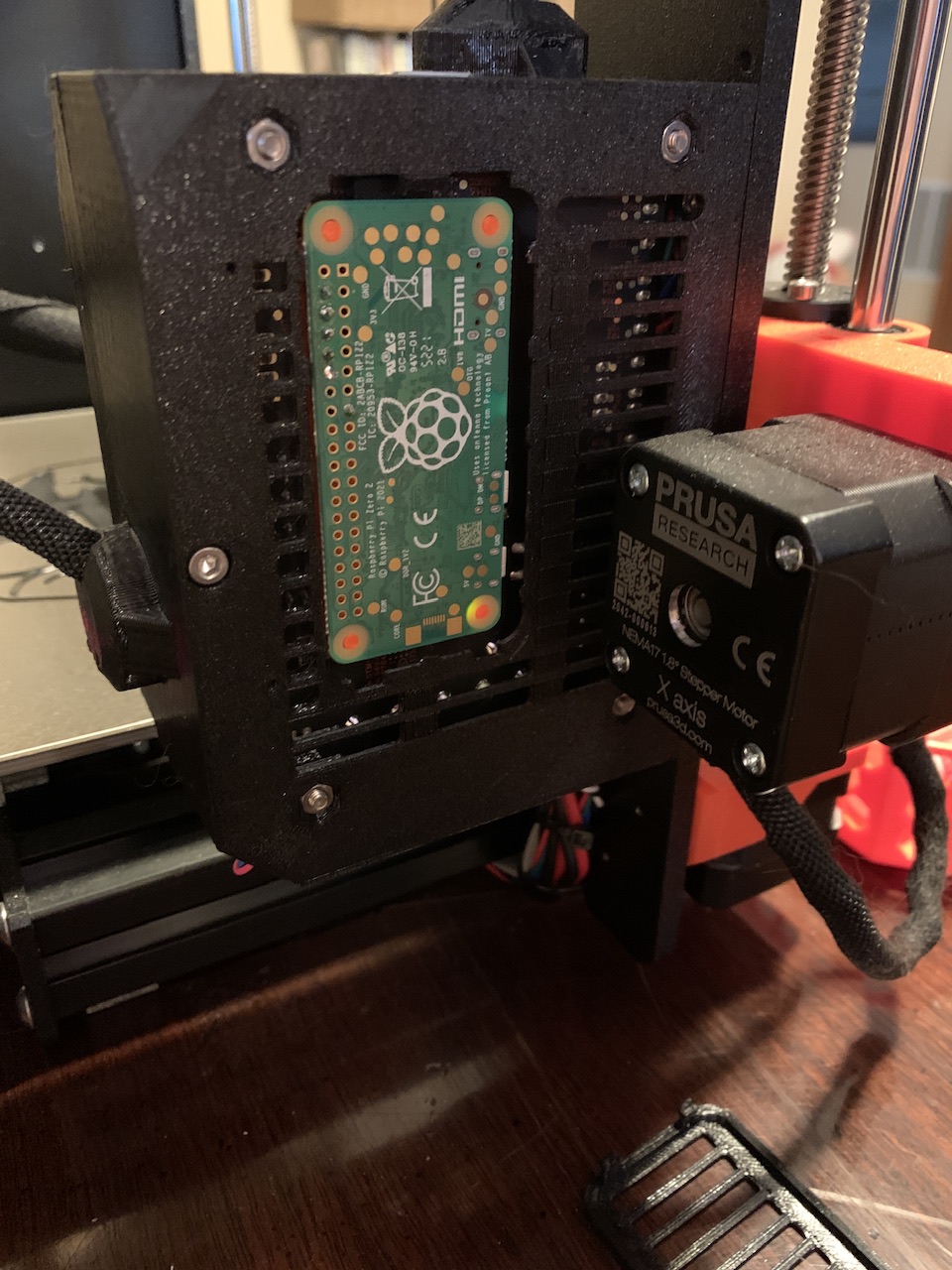

i'm finally running octoprint directly on my prusa mk3s+ via an installed/integrated raspberry pi zero 2 w and octopi. the hardest part was finding and buying the zero 2 w—thankfully they have been showing up in online inventories lately—and the 18mm breakable header. (i also had to hunt down the zero 2 w frame pattern that is a slight remix of the original frame—not linked because there might be some licensing issues in play.)

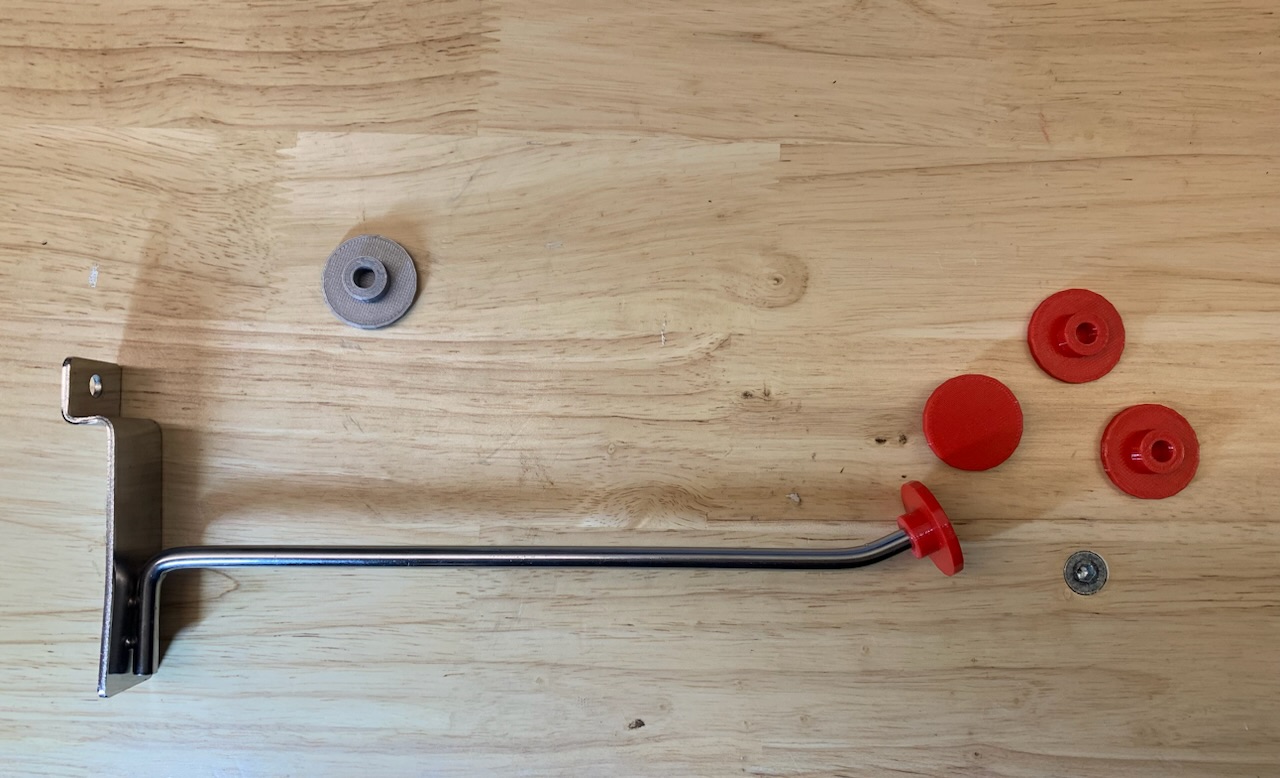

my favorite 3d printer projects have some utility. i recently installed gridwall panels in my shop but didn't want to put an eye out on one of the hooks, so i designed and printed safety caps for the ends.